|

|||||||||||||||||||||||||||

|

|

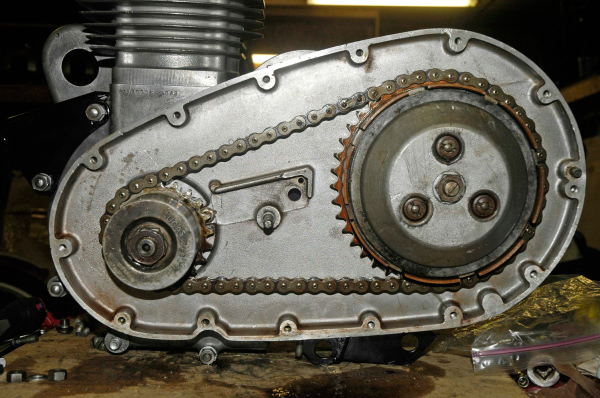

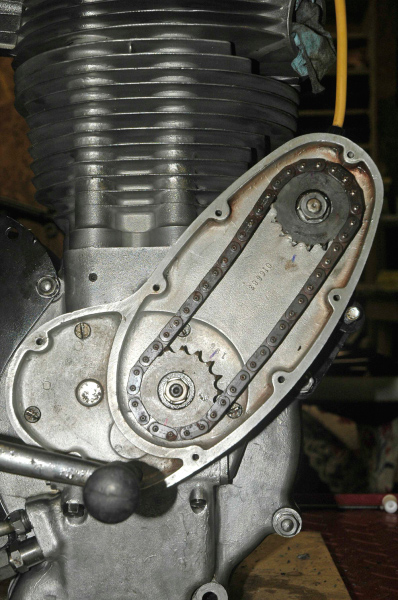

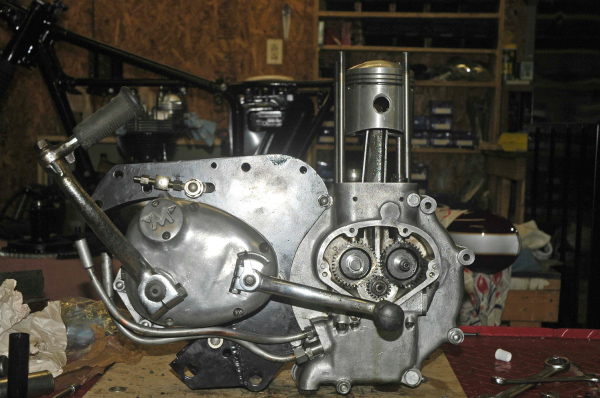

This is another of those very impressive British singles that just look so right. Above the gearbox you can see the adjuster for the primary chain.

All alloy engine with the later alloy primary chaincase. The early Matchless/AJS bikes had a tin chaincase with a band that went around the front and back rim with a screw tightener at the rear end. It was like an enormous hose clip with a semi-circular cross section in which fitted a gasket ring.

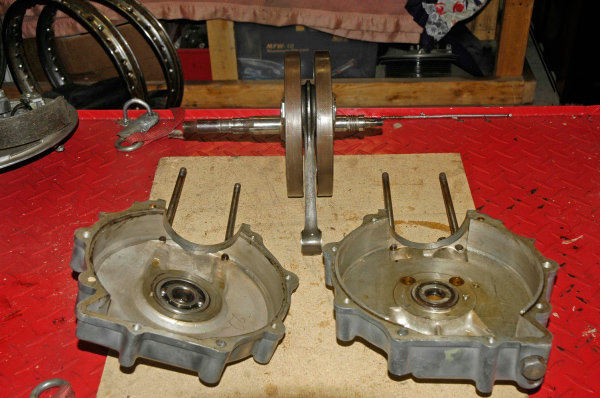

Full diameter flywheels with a double row caged roller main bearing. On the competition engines the crank bolts are torqued to 240 ft/lbs. Not a lot of people have torque wrenches that go that high.

Although the CS designation means that this engine is from the Matchless competition bike, they were also sold as street bikes in the US, hence the alternator

Primary chain is single row. It is tensioned by moving the gearbox backward pivoting on the bottom gearbox mounting bolt. The top mounting bolt is in a slot and has a threaded adjuster.

Designed for heavy work the motor has a single roller bearing on the timing side, but an inner roller, and an outer ball bearing on the drive side.

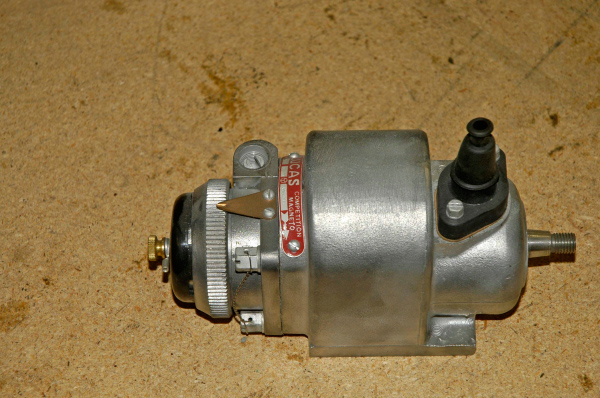

Say what you like about Joe Lucas electrics, the competition magneto gave a huge and consistent spark, even when just spun with your fingers. They are very reliable.

The magneto is driven by a chain which is tensioned by putting shims under the magneto to raise the top sprocket.

Unlike the usual points set up where the ignition cam is in the centre, the magneto has a ring cam. You can see the red heel of the points and the varying thickness of the ring that it bears on. The magneto cable for the manual timing adjustment turns the ring as you pull it so changing the timing.

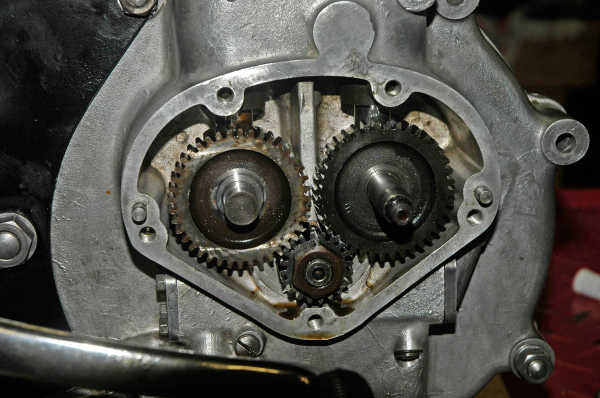

Inlet and exhaust camshafts are driven from a crankshaft pinion. There is one mark on the inlet pinion, but two on the exhaust. One is for road use and one for competition.

Valve timing chest and length of stroke.

Domed piston with valve recesses. It is a big piston and that wide crown takes a lot of BMEP.

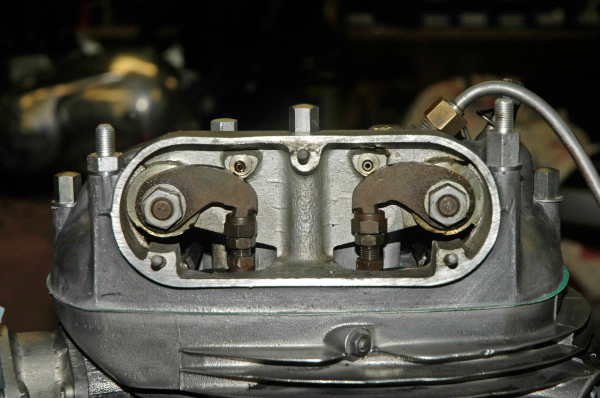

Hands up anybody who recognises the hairpin valve springs. They were popular for competition engines, particularly if high revving, as they do not become coil bound. If a valve spring becomes coil bound the valve is not returned to its seat when it should be and you get valve bounce. This completely upsets the engines breathing and also runs the risk of the valve still being open as the piston comes to the top of its stroke making a collision possible.

The very simple rocker arms are made from flat steel. You can see the valve adjustment on the ends of the pushrods. The setting is nil with a warm engine which makes it impossible to set on the bench.

|

||||||||||||||||||||||||||

Britannia Motorcycles

Old British Bike Specialists

Britannia Motorcycles

Old British Bike Specialists